Services

Engineering Services

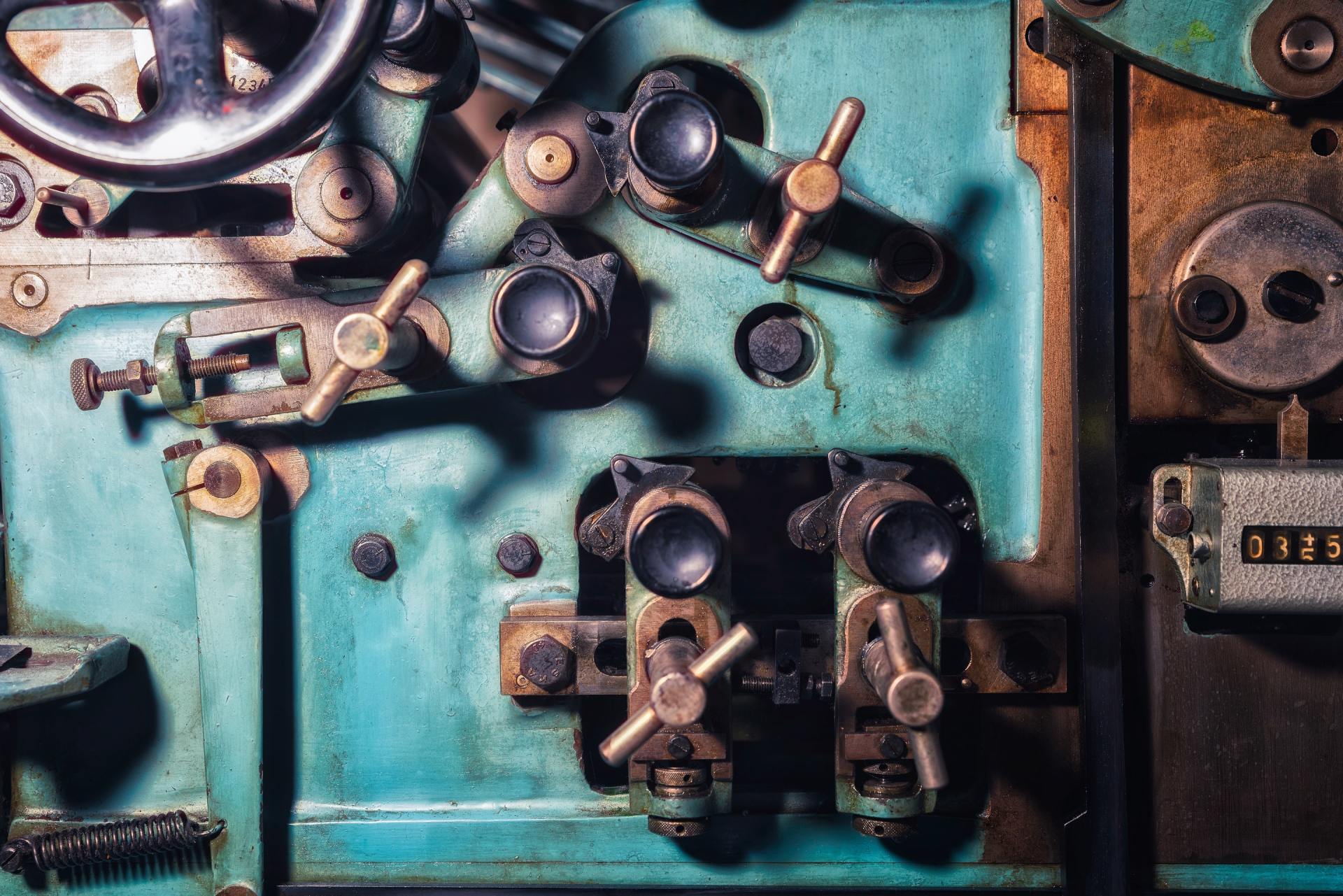

Our main area of expertise is in Aluminium Rolling Mills and Process Lines, although we also have experience in steel and other metals processing and machine design in general, including paper, glass, plastics and fibres.

In collaboration with a group of highly experienced design and project engineers, including Chartered Engineers, we can support you with general engineering services, whether it's an analysis of a machine component failure or a study and report, recommended upgrades, maintenance schedules or general engineering support.

With extensive experience in machine upgrades and modernisations, our team is well placed to advise you on most aspects of a smooth and reliable operation.

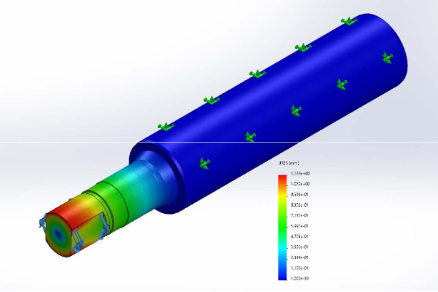

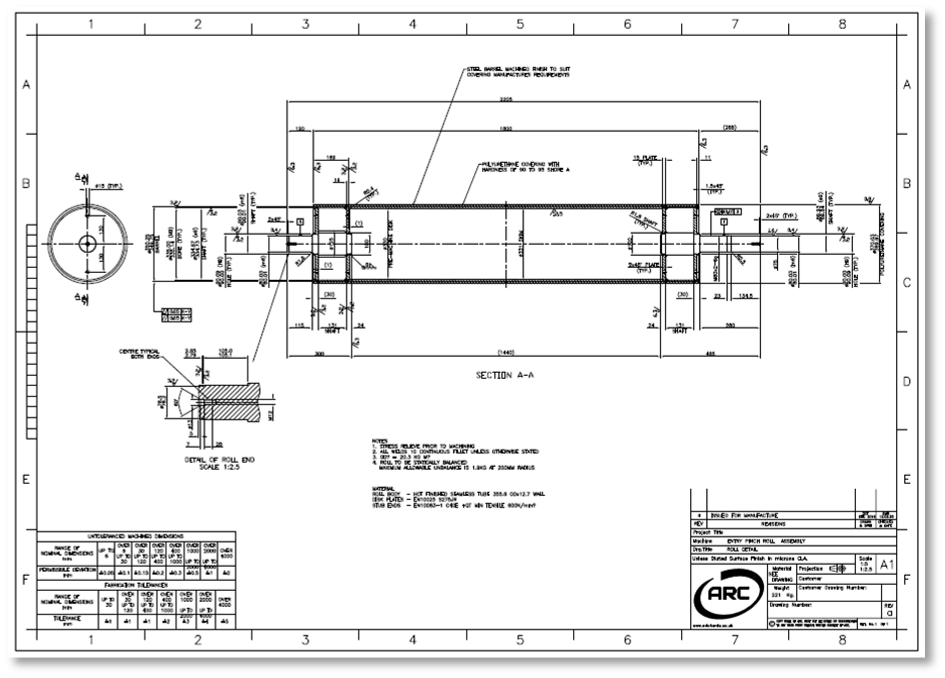

3D Design & Finite Element Analysis (FEA)

In addition to our 2D design using software such as AutoCad, we also have our own in-house Solid Works design package which allows us to design in 3D and use the built in features such as finite element analysis, particularly useful when determining stresses in roll necks, chocks and most other machine components.

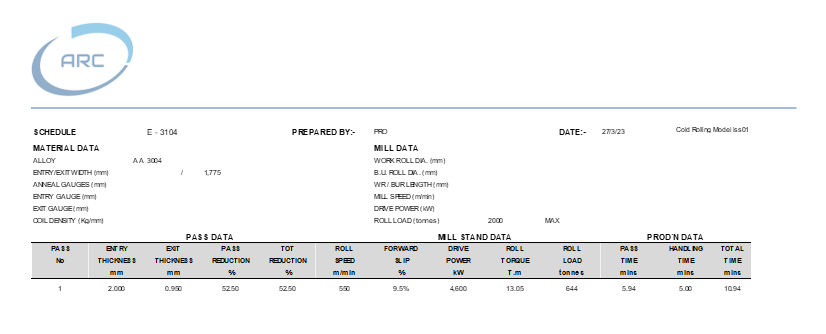

Mill process modelling

ARC has in house models for hot, cold & foil rolling which enables us to simulate pass schedules and calculate torques on the mill for any combination of alloys, speeds, widths and thicknesses.

Engineering Studies

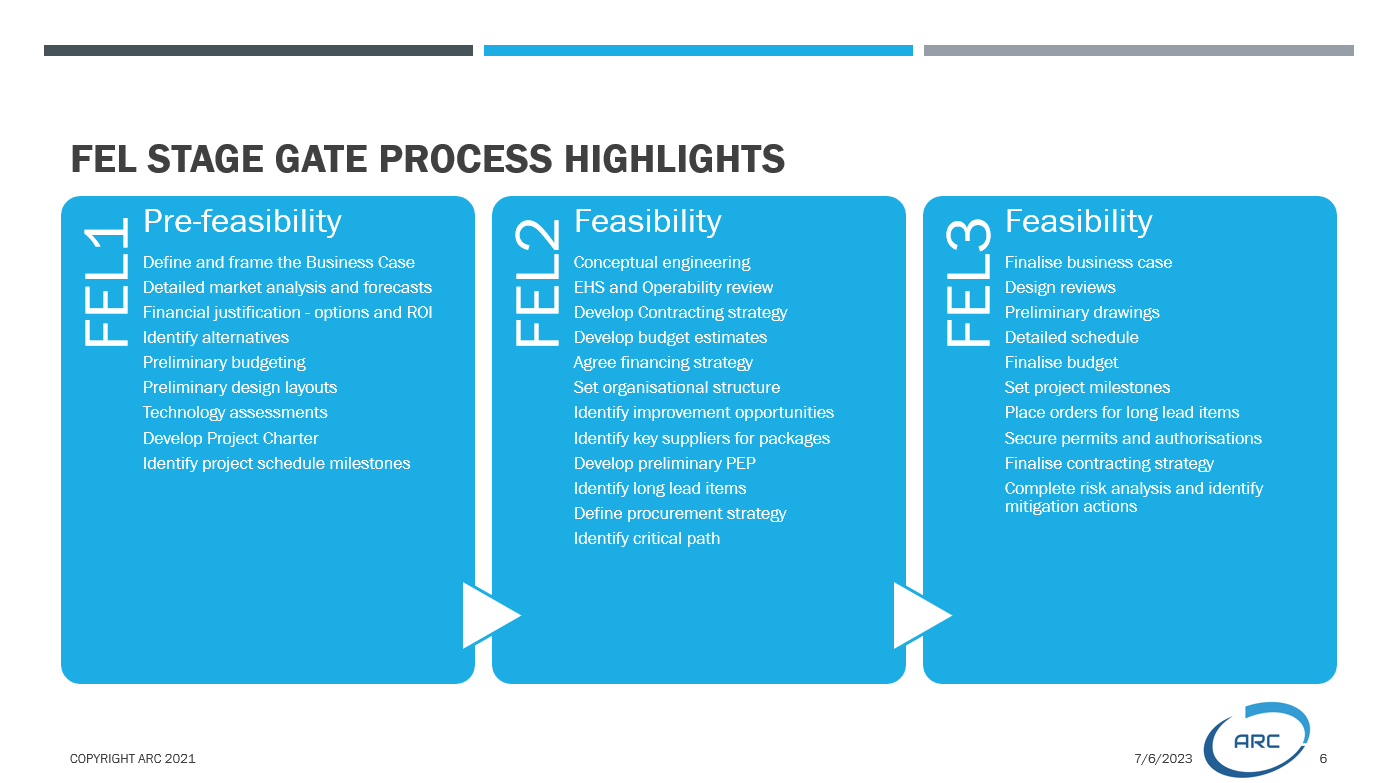

If you are considering a new product as part of your current operation, which may require modification or reconfiguration of your existing production line, we can carry out an engineering study consisting of a site survey, basic design layouts and a detailed report including recommendations for changes and expected budgetary levels. This approach is particularly useful as part of an approval process or funding request and we are fully conversant with gated Front End Loading (FEL) management methodology, from project conception to management and execution

Front End Loading (FEL)

Front-end loading (FEL), also referred to as Pre-Project Planning (PPP), Front-End Engineering Design (FEED), feasibility analysis, conceptual planning, programming / schematic design and early project planning.

The Front End Loading methodology provides for a robust planning and design early in a project’s life cycle and is a proven project delivery system that provides key strategic information for timely go/no-go decision gates.

The FEL process was developed to influence changes in design when the cost to make those changes is relatively low, i.e. at the early stages or ‘Front End’ of project design. In many organisations the effort and attention required in this early phase of project design is critical but often minimized in practice! (Most delays, disruptions, disputes, and cost overruns can be traced back to this phase).

The main objective during the FEL phases is to effectively identify and look to mitigate or manage risk when developing the project.

Due Diligence

Working closely with our partners and clients, our team is able to deliver comprehensive due diligence services that provide in-depth operational, commercial and technical evaluation expertise, consequently adding considerable value to the asset acquisition process.

In 2020 we worked very closely with our partners; Metaquila Ltd and Sustainable Safety Solutions Ltd, to provide desk top and on site due diligence for a multi-million Euro acquisition within the EU metals sector. This acquisition due diligence not only needed to meet the requirements of both corporate entities involved but also that of the European Commission

Asset Integrity

Often an element of Due Diligence, an Asset Integrity Study assesses the condition of equipment in a plant and helps identify potential failures or unplanned events, avoiding expensive downtime and unforeseen CAPEX expenditure.

By having a ‘risk based’ assessment carried out at the site, our clients can understand the potential failures and have a plan identified for them, thus mitigating production down-time and unnecessary expense.

Process Studies

Often, a fairly simple improvement to a production process can save thousands of pounds in costs. However, it is often the case that those closest to the production line don't see the most obvious points for improvement, due mainly to their focus on keeping a line running and reacting to external productivity pressure.

A Process study introduces a 'fresh pair of eyes' and an opportunity to question the process from start to finish without the distractions of productivity demands.

Production & Capacity Optimisation

Ensuring that your production plant is operating at optimum levels and realising its full potential is a fairly easy way of introducing some instant improvements. By using our in-house developed ARC-PRO capacity model, our clients can see at a glance where the production bottlenecks are, how overall efficiency and utilisation are influenced by introducing changes to individual machines, or how the 'tweaking' of production routes and individual products effects the overall output of the plant. An essential tool when considering the introduction of new products and/or new processes, or looking for improvements and bottlenecks in a production line.

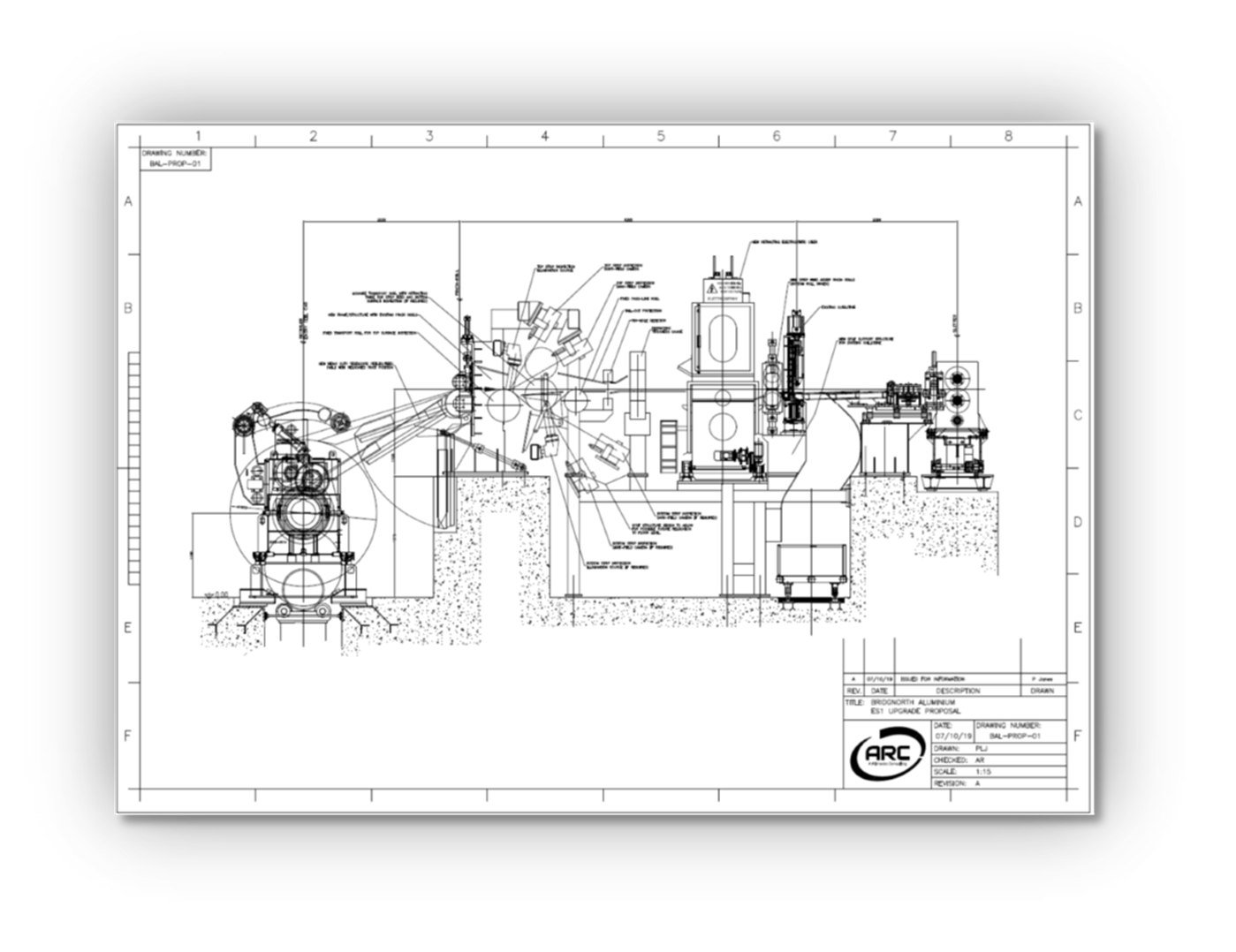

Design & detail drawings

Our team are not only highly experienced in the conceptual design of heavy machinery, but are also expert in the upgrade and modernisation of equipment to be able to cater for increased output, improved product quality or even different product conditions. Our design & detail package includes basic design as we move through an approval process with the client, through to final detail drawings for full production of new components and modernisation of existing equipment. Conversant in Auto CAD and other 3D packages.

Supervision Services

Our Supervision Services include inspection during manufacture, supervision during installation and commissioning and in some cases supervision of new process implementation.

QA & HSE advice

Quality Assurance systems and Health & Safety issues are not only important, but can be very expensive if ignored. As a business owner or factory supervisor you will have many other pressing issues to focus on so let us help you inspect and highlight any problem areas with suggested actions.